Description

Description- Achieves a redundant measure of security via the Dual Retention System on all cylinders and boom pins.

- Lower maintenance costs due to the use of non-lube bearings at all pivots.

- Boom play/maintenance time kept to a minimum with the fiberglass boom’s infinitely adjustable slide pads.

- Lubrication is simplified by having single grease fitting on the rotation bearing.

- Rust and corrosion protection is at its utmost because all components are painted prior to assembly.

- Operators can quickly and positivel verify bolt torque by visually inspecting the torque seal markings.

- Machined rotation bearing mounted surfaces.

- Inside surfaces of each boom are pre-painted prior to assembly.

- Filament wound fiberglass booms.

- No mandatory rebuild periods required, aiding in reduced down times/lowe overall maintenance costs.

- Multiple chassis options as per the lifting platform requirement.

- Easy access to maintenance and repairs

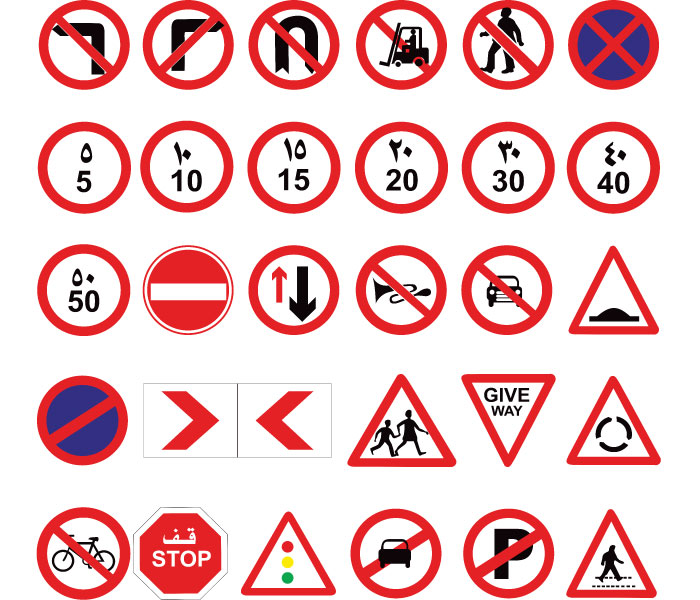

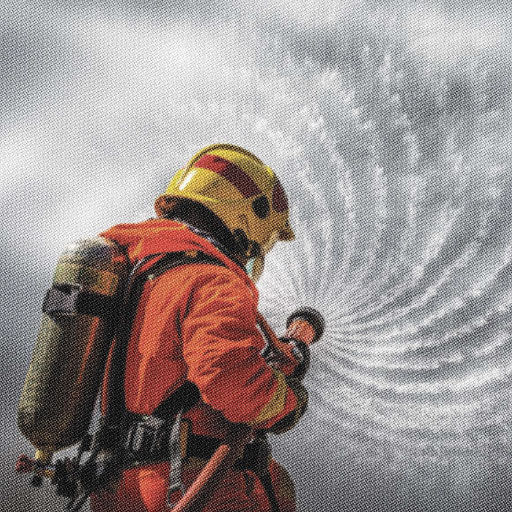

- NAFFCO offers a wide range of Aerial Access Platforms for Line Maintenance, from 9m to 65m working heights.

- NAFFCO partners with world renowned partners to bring in the best in class technology as per ANSI Standards and manufactured in Dubai, UAE.

- These platforms fall under different categories like articulated non-over center, articulated over center, Telescopic and Articulates Telescopic Aerial platforms.

- Our platforms meet ANSI Standards and are CE approved and are known as reliable, high quality products with low maintenance costs.

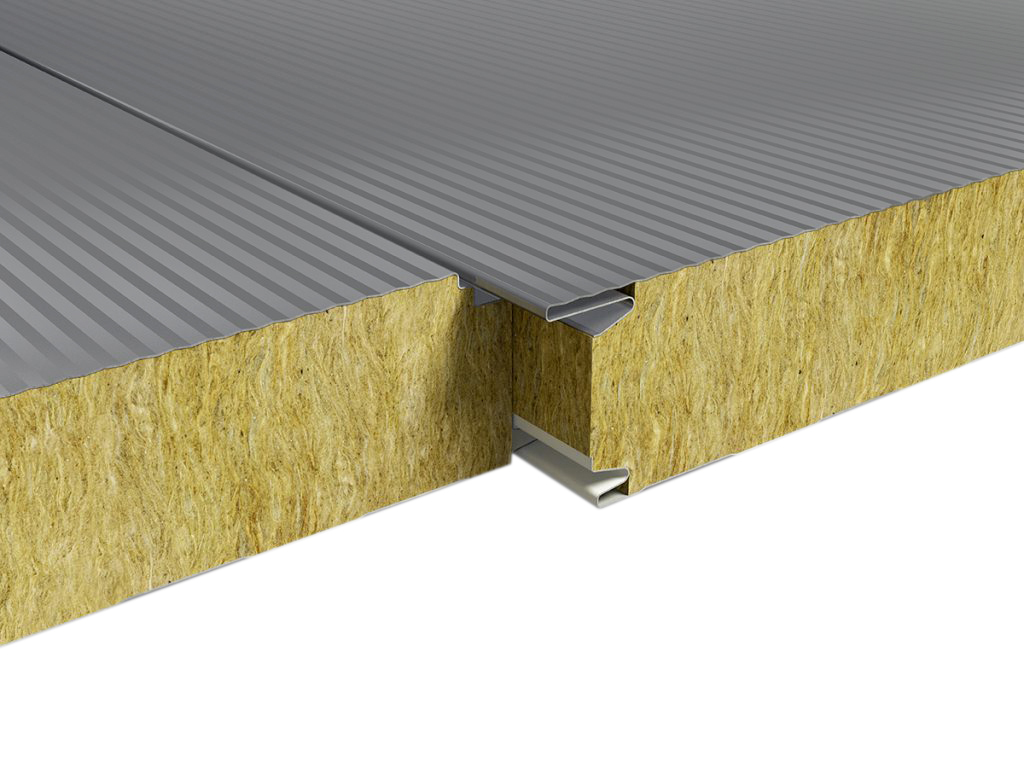

| Falcon-4 | Falcon-6 | Falcon-8 | |

|---|---|---|---|

| Drive | 4x4 | 6x6 | 8x8 |

| Approx. HP | 500 | 700 | 900 |

| Water Tank (L) | 6,500 | 12,500 | 1,600 |

| Foam Tank (L) | 780 | 1,500 | 1,920 |

| Fire Pump Capacity (LPM@10 bar) | 6,000 - 10,000 | 6,000 - 10,000 | 6,000 - 10,000 |

| GVW (T) | 24 | 36 | 52 |